Beschreibung des Produkts:

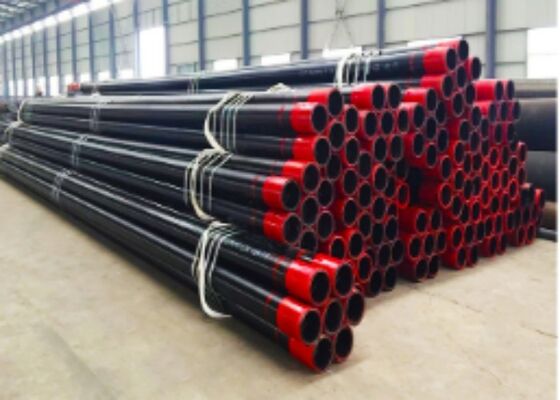

Das API 5CT-Rohr ist ein hochwertiges Produkt, das speziell für die anspruchsvollen Anforderungen der Öl- und Gasindustrie entwickelt wurde.Dieses Rohr ist so konstruiert, dass es außergewöhnliche Festigkeit bietet., Haltbarkeit und Beständigkeit gegen raue Umweltbedingungen, was es zu einer idealen Wahl für Bohrungen macht.Die API 5CT-Rohre werden aufgrund ihrer überlegenen mechanischen Eigenschaften und zuverlässigen Leistung in den anspruchsvollsten Downhole-Umgebungen weit verbreitet als Bohrrohre verwendet.

Eine der wichtigsten Eigenschaften der API 5CT-Rohre ist ihre Verfügbarkeit in einer Vielzahl von Außendurchmessern von 21,9 mm bis zu einem beeindruckenden 812,8 mm.Diese große Größenpalette ermöglicht vielseitige Anwendungen in verschiedenen Bohrszenarien, die von kleinen Explorationsbohrungen bis hin zu großen Produktionsbohrungen ausgestattet sind.Die nahtlose Konstruktion der Schläuche sorgt für eine gleichmäßige Festigkeit und beseitigt die Gefahr, dass Schweißnähte unter Druck versagen, was für die Aufrechterhaltung der Bohrungsintegrität von entscheidender Bedeutung ist.

Die Materialzusammensetzung der API 5CT-Rohre umfasst mehrere Sorten wie K55, N80, L80 und P110.mit unterschiedlicher Zugfestigkeit, Ausbeutefestigkeit und Korrosionsbeständigkeit. Zum Beispiel wird K55 häufig für allgemeine Bohranwendungen verwendet,während die N80- und L80-Klassen in anspruchsvolleren oder ätzenden Umgebungen eine verbesserte Leistung bietenP110, einer der höchsten Festigkeitsgrade, eignet sich für tiefe Bohrungen und Hochdruckanwendungen.Diese Materialpalette sorgt dafür, dass die API 5CT-Rohre auf die genauen Bedürfnisse jedes Bohrvorhabens zugeschnitten werden können.

Zusätzlich zu seinem robusten Material und seinen Dimensionseigenschaften ist das API 5CT-Rohr mit verschiedenen Gewindeformen wie Rund, Stützfeder und Spezialbevel erhältlich.Diese Gewindeentwürfe sind so konzipiert, dass sie sichere und undichte Verbindungen zwischen den Rohrbereichen bieten, die für die Aufrechterhaltung der Druckintegrität des Bohrbohrs entscheidend ist.während der Buttress-Dreh eine überlegene axiale Lastkapazität bietetSpezielle Schlägerfäden sind für spezifische Anwendungsfälle konzipiert, um die Kompatibilität mit einer Vielzahl von Bohrgeräten zu gewährleisten und die allgemeine Zuverlässigkeit der Rohrstrang zu verbessern.

Die Oberflächenbehandlungsmöglichkeiten für die API 5CT-Rohre verbessern ihre Leistung und Langlebigkeit weiter.und Lackierung zum Schutz der Rohre vor KorrosionDie Phosphatisierung erzeugt eine Schutzschicht, die die Anhaftung und Rostbeständigkeit der Farbe verbessert.Schwarzen bietet eine einheitliche und langlebige Oberflächenveredelung, die die Oberflächenreibung reduziertDiese Oberflächenbehandlungen sind unerlässlich, um die Lebensdauer von Bohrrohren zu verlängern.Vor allem bei aggressiven Abgründungsbedingungen, bei denen die Exposition gegenüber korrosiven Flüssigkeiten und hohen Temperaturen üblich ist.

Insgesamt ist das API 5CT-Rohr eine zuverlässige und vielseitige Wahl für Bohrrohranwendungen.und anpassbare Gewindeformen machen es gut geeignet, die vielfältigen Herausforderungen in der Bohrindustrie zu bewältigenIn Kombination mit fortschrittlichen Oberflächenbehandlungen sorgt dieses Rohr für langlebige Leistung, Sicherheit und Effizienz im Bohrbetrieb.Die API 5CT-Rohre zeichnen sich als erstklassiges Produkt aus, das zur Optimierung der Bohrproduktivität und zum Erhalt der Bohrungsintegrität unter anspruchsvollen Bedingungen entwickelt wurde..

Eigenschaften:

- Produktbezeichnung: API 5CT Schläuche

- Inspektion: Inspektion durch Dritte, Prüfbescheinigung, SGS, BV, DNV

- Verbindungsart: EUE, NUE, STC, LTC, BTC

- Oberflächenbehandlung: Phosphating, Schwarzen, Lacken

- Garnform: rund, mit Stützfläche, spezieller Bevel

- Materialoptionen: K55, N80, L80, P110

- mit einer Breite von mehr als 20 mm,

- Ideal für Bohrrohranwendungen

Technische Parameter:

| Material |

K55, N80, L80, P110 |

| Verbindungsart |

EUE, NUE, STC, LTC, BTC |

| Typ |

Nahtlose Stahlrohre |

| Verbindung |

Schweißen |

| Inspektion |

Prüfung durch Dritte, Prüfbescheinigung, SGS, BV, DNV |

| Fadenform |

Rund, Stützfläche, spezielle Bevel |

| Standards |

Die Anforderungen an die Qualität der Produkte sind in Anhang I der Verordnung (EU) Nr. 1308/2013 festgelegt. |

| Maschinentyp |

Bohrgeräte |

| Außendurchmesser |

21.9 - 812.8 mm |

| Oberflächenbehandlung |

Phosphating, Schwarzen und Lacken |

Anwendungen:

API 5CT Tubing ist ein in China hergestelltes, hochwertiges, nahtloses Stahlrohr, das speziell für anspruchsvolle Anwendungen in der Öl- und Gasindustrie entwickelt wurde.Zertifiziert nach ISO 9001 und in Übereinstimmung mit den Standards API Spec 5CT und ISO 11960Die robuste Konstruktion und der präzise Herstellungsprozess machen sie ideal für den Einsatz als Ölfeldrohr,bei denen Haltbarkeit und Beständigkeit gegenüber rauen Umgebungen von entscheidender Bedeutung sind.

Einer der wichtigsten Anwendungsbereiche für API 5CT-Rohre ist der Bohrbetrieb.Es spielt eine wichtige Rolle im Extraktionsprozess, indem es einen sicheren und stabilen Kanal für den Transport von Flüssigkeiten und Gasen zwischen dem Bohrloch und der Oberfläche bietetDie nahtlose Konstruktion der Schläuche verringert das Risiko von Lecks und Ausfällen unter hohen Druck- und Temperaturbedingungen, die in Bohrszenarien üblich sind.

Dieses Rohrprodukt eignet sich auch für verschiedene andere Anwendungen auf Ölfeldern, einschließlich Rohr und Gehäuse für die Produktion.Der Schweißverbindungsart und die Verfügbarkeit verschiedener Gewindeformen wie rundDiese Eigenschaften erleichtern die einfache Installation und Integration in die bestehende Bohrinfrastruktur.

API 5CT Tubing wird effizient in Bündel und Gewebe verpackt, um einen sicheren Transport und eine sichere Lagerung zu gewährleisten.Es bietet Flexibilität und rechtzeitige Lieferung für GroßprojekteDie Zahlungsbedingungen sind vielseitig, einschließlich LC und TT, um internationale Käufer zu bedienen und reibungslose Transaktionen zu gewährleisten.

Darüber hinaus werden die Produkte strengen Qualitätskontrollmaßnahmen unterzogen, einschließlich einer Kontrolle durch Dritte, Prüfzeugnisse und Zertifizierungen von SGS, BV und DNV.Dieses umfassende Prüfverfahren gewährleistet, dass jede Serie von Rohren strengen Qualitätsstandards entspricht, die den Benutzern bei kritischen Bohrungen Vertrauen geben.

Zusammenfassend kann gesagt werden, dass API 5CT-Rohre eine wesentliche Komponente für Ölfeld- und Bohrrohranwendungen sind, die Festigkeit, Zuverlässigkeit und Übereinstimmung mit internationalen Standards bieten.Die nahtlose Konstruktion, vielseitige Anschlussmöglichkeiten und eine gründliche Inspektion machen es zu einer ausgezeichneten Wahl für anspruchsvolle Bohr- und Ölfeldumgebungen.

Anpassung:

Unser aus China stammendes und nach ISO 9001 zertifiziertes API 5CT-Rohrprodukt bietet qualitativ hochwertige Rohrlösungen für Ölfelder, die auf Ihre spezifischen Bedürfnisse zugeschnitten sind.Wir sind spezialisiert auf die Anpassung von Öl- und Gasrohren., die Einhaltung der API-Spezifikation 5CT und der ISO 11960-Normen gewährleistet.

Wir bieten eine Mindestbestellmenge von 1 Tonne, mit Verpackungsdetails einschließlich sicherer Bündel und Gewebebeutel, um die Schläuche während des Transports zu schützen.und wir akzeptieren flexible Zahlungsbedingungen wie LC, TT und andere.

Unsere API 5CT-Rohre sind in Materialien wie K55, N80, L80 und P110 erhältlich, mit Oberflächenbehandlungen wie Phosphating, Schwarzen und Lacken, um Haltbarkeit und Leistung zu verbessern.Die Verbindungen werden durch zuverlässige Schweißtechniken hergestellt, um die Strukturintegrität zu gewährleisten.

Um die höchste Qualität zu gewährleisten, werden alle Produkte strengen Inspektionsverfahren unterzogen, darunter die Inspektion durch Dritte, Werkzeugprüfzertifikate, SGS-, BV- und DNV-Zertifizierungen.Vertrauen Sie auf unsere API 5CT-Rohre für Ihre Ölfeldrohre und Öl- und Gasrohre Anforderungen mit maßgeschneiderten Service und professionellen Unterstützung.

Unterstützung und Dienstleistungen:

Unsere Produkttechnische Unterstützung und Dienstleistungen für API 5CT-Rohre sind so konzipiert, dass Sie bei Ihren Bohrungen eine optimale Leistung und Zuverlässigkeit gewährleisten.Wir bieten umfassende technische Unterstützung, einschließlich der Anleitung bei der Auswahl der MaterialienUnser Expertenteam bietet Unterstützung bei Inspektionen, Tests,und Zertifizierungsprozesse zur Gewährleistung der Qualität und Integrität der Rohre.

Darüber hinaus beraten wir Sie über die beste Installationspraxis, Korrosionsbeständigkeit und Wartungsverfahren, um die Lebensdauer der Rohre zu verlängern.Maßgeschneiderte Schulungen und Unterstützung bei der Fehlerbehebung stehen zur Verfügung, um Ihrem Team zu helfen, API 5CT-Rohrprodukte in verschiedenen Brunnenbedingungen effektiv zu handhaben und zu nutzen.

Wir verpflichten uns, Ihnen umgehende und professionelle Dienstleistungen zur Bewältigung technischer Herausforderungen zu bieten, um sicherzustellen, dass Ihr Betrieb mit unseren hochwertigen API 5CT-Rohrleitungen reibungslos und effizient abläuft.

Verpackung und Versand:

Die API 5CT-Rohre sind sorgfältig verpackt, um einen maximalen Schutz während des Transports und der Handhabung zu gewährleisten.dann mit Stahlgurt fest gebundenDie Bündel werden auf Holz- oder Metallschlitten geladen und mit einem wasserdichten Material umhüllt, um vor Feuchtigkeit und Umweltbelastungen zu schützen.

Für den Versand werden die Schläuche je nach Bestellgröße und Bestimmungsort in Containern oder auf Flachbettfahrzeugen angeordnet.Sicherstellung einer sicheren Lieferung an den Standort des KundenDie entsprechenden Unterlagen und Handhabungsanweisungen müssen jeder Sendung beigefügt werden, um eine reibungslose Zollabfertigung und Handhabung zu erleichtern.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!