Product Description:

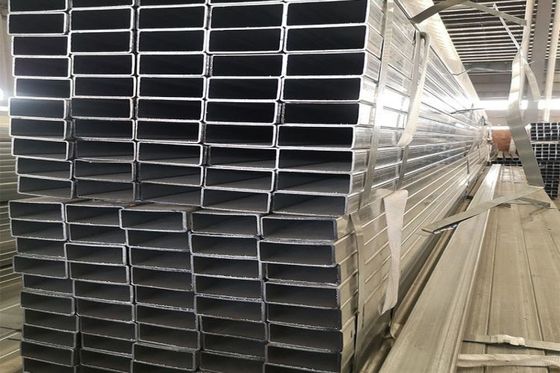

The LSAW Steel Pipe is a high-quality, robust piping solution widely utilized in various industrial and construction applications. Manufactured through the Longitudinal Submerged Arc Welding process, this steel round tube offers superior structural integrity and durability, making it an ideal choice for demanding projects. With a broad range of outside diameters available from 355.6mm to 2320mm, the LSAW Steel Pipe can be tailored to meet specific requirements, providing versatility across numerous sectors.

One of the key features of the LSAW Steel Pipe is its comprehensive inspection process, ensuring the highest standards of quality and safety. Each pipe undergoes rigorous testing methods such as Hydraulic Testing, Eddy Current inspection, Radiographic Testing (RT), and Ultrasonic Testing (UT). Additionally, the product can be inspected by third-party agencies to guarantee compliance with international standards and customer specifications. This meticulous inspection regime ensures that every pipe delivered is free from defects and capable of withstanding extreme operational conditions.

The LSAW Steel Pipe conforms to several prominent industry standards, including API 5L, EN10219, EN10210, and ASTM A252, among others. These standards cover various aspects such as material composition, mechanical properties, and dimensional tolerances, ensuring that the pipes meet global requirements for performance and reliability. Whether the application involves oil and gas transportation, structural frameworks, or piling construction, these certified pipes provide assurance of quality and consistency.

Surface treatment options for the LSAW Steel Pipe are diverse, catering to different environmental and functional needs. Customers can choose from bare pipes or those coated with varnish coating or anti-rust oil for basic corrosion protection. Advanced coatings such as Fusion Bonded Epoxy (FBE), 3-layer Polyethylene (3PE), and 3-layer Polypropylene (3PP) are also available to enhance durability and resistance against harsh chemical and weather conditions. Additionally, galvanized coatings, coal tar epoxy, and concrete coatings are offered for specific applications requiring superior corrosion resistance and mechanical protection. Notably, the 2 inch galvanized pipe variant provides excellent rust-prevention qualities, making it highly suitable for outdoor and industrial environments.

In terms of usage, the LSAW Steel Pipe is exceedingly versatile. It is extensively used as a structure pipe in building and infrastructure projects, where strength and reliability are paramount. Its robust construction makes it suitable for pipe piling in construction activities, providing stable foundations and support for various structures. The availability of galvanised steel pipe options further enhances its applicability in environments prone to moisture and corrosion, extending the lifespan of the installation.

Moreover, the LSAW Steel Pipe is recognized for its compatibility with diverse construction and engineering requirements. Its ability to be fabricated and installed with ease, combined with its superior mechanical properties, makes it a preferred choice among engineers and contractors. Whether in large-scale infrastructure projects or specialized industrial installations, this steel round tube delivers consistent performance and dependable service.

In summary, the LSAW Steel Pipe stands out as a premium product that combines advanced manufacturing techniques, stringent quality inspections, and a wide array of customizable features. Its adherence to international standards such as API 5L and ASTM A252, coupled with multiple surface treatment options including galvanization and epoxy coatings, ensures it meets the highest industry benchmarks. With diameters ranging from 355.6mm to 2320mm and suitability for structural and piling applications, it offers a comprehensive solution for modern construction challenges. Whether you require a durable 2 inch galvanized pipe for corrosion resistance or a large-diameter steel round tube for structural integrity, the LSAW Steel Pipe is engineered to satisfy your project’s demands efficiently and reliably.

Features:

-

Product Name: LSAW Steel Pipe

-

Outside Diameter: 355.6mm - 2320mm

-

Wall Thickness: 5mm - 50mm

-

Inspection Methods: Hydraulic Testing, Eddy Current, RT, UT, or Inspection by 3rd Party

-

Standard Compliance: API 5L, EN10219, EN10210, ASTM A252, etc.

-

Usage: Structure Pipe, Pipe Piling Construction

-

Suitable for applications requiring galvanised steel pipe

-

Available options include 2 inch galvanized pipe for versatile construction needs

-

High-quality 2 inch galvanized pipe ensuring durability and corrosion resistance

Technical Parameters:

|

Usage

|

Structure Pipe, Pipe Piling Construction

|

|

Steel Grade

|

API 5L: GR B, X42, X46, X56, X60, X65, X70; ASTM A53: GR A, GR B, GR C

|

|

Transport Package

|

Black Paint, Bevel Send, End Caps

|

|

Outside Diameter

|

355.6mm - 2320mm

|

|

Standard

|

API 5L, EN10219, EN10210, ASTM A252 Etc

|

|

Welded Line Type

|

Longitudinal

|

|

Wall Thickness

|

5mm - 50mm

|

|

Surface Treatment

|

Bare, Varnish Coating/Anti Rust Oil, FBE, 3PE, 3PP, Galvanized, Coal Tar Epoxy, Concrete Coating

|

|

Inspection

|

With Hydraulic Testing, Eddy Current, RT, UT Or Inspection By 3rd Party

|

Applications:

The JOHO LSAW Steel Pipe, originating from China and certified under ISO 9001, is a versatile and reliable product designed to meet a wide range of industrial applications. This steel round tube is manufactured with precision, featuring a longitudinal welded line type that ensures structural integrity and durability. With an outside diameter ranging from 355.6mm to 2320mm and a wall thickness between 5mm and 50mm, these pipes are suitable for various demanding construction and engineering projects.

One of the key application occasions for JOHO’s LSAW Steel Pipe is in the oil and gas industry. These pipes are extensively used for pipeline transportation of oil, natural gas, and water due to their high strength and corrosion resistance. The availability of multiple surface treatments such as bare, varnish coating, anti-rust oil, FBE, 3PE, 3PP, galvanized, coal tar epoxy, and concrete coating allows for customization based on environmental conditions and specific project requirements. For instance, the 2 inch galvanized pipe and galvanized metal pipe variants are particularly favored in outdoor installations where resistance to rust and weather elements is critical.

In the construction sector, JOHO LSAW steel pipes are utilized for structural support, piling, and infrastructure development. Their robust wall thickness and large diameter make them ideal for heavy-duty applications such as bridges, buildings, and industrial facilities. The product’s transport package, which includes black paint, bevel send, and end caps, ensures safe and secure delivery. With a minimum order quantity of just 1 ton and competitive pricing between USD 650 and USD 1500, these pipes provide an economical solution without compromising on quality.

Additionally, JOHO’s LSAW Steel Pipes are employed in water supply systems, sewage treatment plants, and marine engineering projects. Their excellent weld quality and comprehensive surface treatment options help extend the service life even in harsh environments. The delivery time is guaranteed within 30 days, with flexible payment terms such as LC and TT, making it convenient for global buyers to procure these steel round tubes.

In summary, the JOHO LSAW Steel Pipe product line offers a highly adaptable and durable solution for industries requiring reliable steel piping. Whether it is the galvanized metal pipe for corrosion resistance or the 2 inch galvanized pipe used in smaller diameter applications, JOHO provides a certified, high-quality product tailored to diverse industrial needs.

Customization:

JOHO offers high-quality LSAW steel pipes manufactured in CHINA, certified with ISO 9001 to ensure superior standards. Our steel round tube products are available in various steel grades including API 5L (GR B, X42, X46, X56, X60, X65, X70) and ASTM A53 (GR A, GR B, GR C), with outside diameters ranging from 355.6mm to 2320mm.

We specialize in producing galvanised water pipe and galvanised steel pipe options with a longitudinal welded line type, tailored to meet your specific requirements. The pipes come with transport packaging options such as black paint, bevel send, and end caps to ensure safe delivery.

Our minimum order quantity is 1 TON, with prices ranging from USD 650 to USD 1500 depending on specifications. Packaging details are customizable as per customer request. Delivery is guaranteed within 30 days, and payment terms include LC, TT, and other common methods.

All LSAW steel pipes undergo rigorous inspection including hydraulic testing, eddy current, radiographic testing (RT), ultrasonic testing (UT), or inspection by a third party to maintain quality assurance.

Support and Services:

Our LSAW Steel Pipe product is supported by a comprehensive technical support and services program designed to ensure optimal performance and customer satisfaction. We provide expert consultation on product selection, application, and installation to help you achieve the best results in your projects.

Technical support includes detailed documentation, engineering guidance, and troubleshooting assistance. Our team of specialists is available to address any questions related to material specifications, welding procedures, and quality standards compliance.

We also offer on-site inspection and testing services to verify the integrity and quality of the LSAW Steel Pipes during and after installation. This includes non-destructive testing methods such as ultrasonic testing and radiographic inspection.

Additionally, we provide customized solutions tailored to your specific requirements, including special coatings, dimensions, and grades. Our commitment extends beyond delivery, with ongoing maintenance advice and support to maximize the lifespan and reliability of your piping systems.

By choosing our LSAW Steel Pipe, you gain access to a dedicated support network focused on delivering technical excellence and service quality throughout the lifecycle of your project.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!