Product Description:

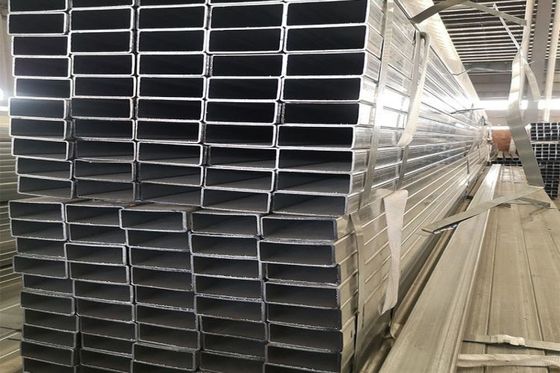

The LSAW Steel Pipe is a high-quality structural pipe specifically engineered for demanding applications such as structural pipework and pipe piling construction. Known for its durability and strength, this pipe is an ideal choice for projects requiring robust support and reliable performance under heavy loads and challenging environmental conditions. The LSAW (Longitudinal Submerged Arc Welded) manufacturing process ensures superior weld integrity and uniform wall thickness, making it a preferred option in the construction and infrastructure sectors.

These steel pipes come in a wide range of outside diameters, from 355.6mm up to 2320mm, accommodating various project requirements. Among its versatile applications, the 24 inch steel pipe variant is particularly popular in large-scale industrial and construction projects due to its optimal size and strength characteristics. The product can also be utilized as galvanised steel pipe or galvanised water pipe, offering excellent corrosion resistance and longevity when exposed to water or other corrosive elements.

In terms of quality and standards, the LSAW Steel Pipe meets internationally recognized specifications, including API 5L, EN10219, EN10210, and ASTM A252. Compliance with these standards guarantees that every pipe produced maintains high mechanical properties and dimensional accuracy. This adherence to standards also facilitates seamless integration into global construction projects and pipeline systems, ensuring compatibility and reliability.

The transport packaging of the LSAW Steel Pipe is carefully designed to protect the product during shipping and handling. Each pipe is coated with black paint to prevent rust and corrosion during transportation. Additionally, beveling is applied to pipe ends to facilitate welding and installation on-site, while end caps are provided to shield the pipe interior from contaminants and damage. This comprehensive packaging approach ensures that the pipes arrive at the construction site in optimal condition, ready for immediate use.

Inspection and quality assurance are critical components of the LSAW Steel Pipe manufacturing process. Each pipe undergoes rigorous testing methods to verify its integrity and performance. Hydraulic testing ensures the pipe can withstand high internal pressures without failure, while non-destructive testing methods such as Eddy Current testing, Radiographic Testing (RT), and Ultrasonic Testing (UT) are employed to detect any internal or surface defects. Furthermore, inspection by third-party agencies is available, providing an additional layer of assurance regarding product quality and compliance with project specifications.

The LSAW Steel Pipe is an excellent choice for applications requiring durable and reliable piping solutions. Whether used as a galvanised steel pipe for enhanced corrosion resistance or as a galvanised water pipe for safe water transportation, it offers a combination of strength, quality, and versatility. Its availability in a broad range of diameters, including the commonly utilized 24 inch steel pipe size, makes it adaptable to various construction and infrastructure projects, from pipeline systems to structural supports and piling foundations.

Overall, the LSAW Steel Pipe stands out as a premium piping product that meets the rigorous demands of modern construction and industrial needs. Its compliance with international standards, comprehensive inspection protocols, and robust packaging make it a trustworthy component for engineers and contractors aiming for long-lasting and efficient project outcomes. Whether for structural pipe applications or pipe piling construction, this steel pipe delivers exceptional performance, ensuring safety and durability across all use cases.

Features:

-

Product Name: LSAW Steel Pipe

-

Outside Diameter: 355.6mm - 2320mm

-

Wall Thickness: 5mm - 50mm

-

Inspection Methods: Hydraulic Testing, Eddy Current, RT, UT, or Inspection by 3rd Party

-

Surface Treatment Options: Bare, Varnish Coating/Anti Rust Oil, FBE, 3PE, 3PP, Galvanized, Coal Tar Epoxy, Concrete Coating

-

Transport Package: Black Paint, Bevel Send, End Caps

-

Suitable for applications requiring 2 inch galvanized pipe and galvanised steel pipe

-

High-quality galvanised steel pipe ensuring durability and corrosion resistance

Technical Parameters:

|

Welded Line Type

|

Longitudinal

|

|

Steel Grade

|

API 5L: GR B, X42, X46, X56, X60, X65, X70; ASTM A53: GR A, GR B, GR C

|

|

Outside Diameter

|

355.6mm - 2320mm (including 24 inch steel pipe)

|

|

Wall Thickness

|

5mm - 50mm

|

|

Transport Package

|

Black Paint, Bevel Send, End Caps

|

|

Usage

|

Structure Pipe, Pipe Piling Construction

|

|

Inspection

|

With Hydraulic Testing, Eddy Current, RT, UT or Inspection By 3rd Party

|

|

Surface Treatment

|

Bare, Varnish Coating/Anti Rust Oil, FBE, 3PE, 3PP, Galvanized (ideal for galvanized metal pipe and 2 inch galvanized pipe), Coal Tar Epoxy, Concrete Coating

|

|

Standard

|

API 5L, EN10219, EN10210, ASTM A252 Etc

|

Applications:

The JOHO LSAW Steel Pipe, originating from China and certified with ISO 9001, is a premium product designed to meet the rigorous demands of various industrial applications. With a wall thickness ranging from 5mm to 50mm and an outside diameter between 355.6mm and 2320mm, these longitudinal welded pipes are manufactured using high-quality steel grades such as API 5L (GR B, X42, X46, X56, X60, X65, X70) and ASTM A53 (GR A, GR B, GR C). This versatility in specifications ensures that JOHO LSAW Steel Pipes are suitable for a wide range of occasions and scenarios requiring robust and reliable piping solutions.

One of the primary application occasions for JOHO LSAW Steel Pipes is in the construction and infrastructure sector, where galvanized metal pipe and galvanised water pipe are essential for water transportation, sewage, and irrigation systems. The galvanization process provides excellent corrosion resistance, making these pipes ideal for outdoor and underground installations where durability against environmental factors is critical. Their large diameter and strong wall thickness make them perfect for high-pressure water conveyance and distribution networks.

In the oil and gas industry, JOHO LSAW Steel Pipes are extensively used for pipeline transportation of natural gas, crude oil, and refined products. The compliance with API 5L standards and rigorous inspection methods, including hydraulic testing, eddy current, radiographic testing (RT), ultrasonic testing (UT), or inspection by third parties, ensures the pipes’ integrity and safety under extreme operating conditions. These pipes are often utilized in onshore and offshore pipeline projects where reliability and longevity are paramount.

Another significant application scenario includes mechanical and structural engineering projects, where galvanized metal pipe is preferred for its strength and resistance to wear and tear. The pipes can be used in the fabrication of heavy machinery, bridge construction, and large-scale industrial plants, supporting structural integrity and enhancing safety standards.

JOHO offers flexible packaging details as per customer requirements and guarantees delivery within 30 days, ensuring timely project execution. The minimum order quantity is 1 TON, and pricing ranges from USD 650 to USD 1500 depending on specifications and order volume. Payment terms are convenient, including LC, TT, and other modes, facilitating smooth and secure transactions globally.

In summary, JOHO’s LSAW Steel Pipes are indispensable in scenarios demanding galvanized metal pipe or galvanised water pipe solutions, including water supply systems, oil and gas pipelines, and heavy industrial applications. Their robust construction, certified quality, and customizable options make them a trustworthy choice for engineers and project managers worldwide.

Customization:

JOHO offers customizable LSAW steel pipe products originating from CHINA, certified with ISO 9001 to ensure high quality standards. Our steel round tube products, including the popular 24 inch steel pipe, are designed to meet diverse industrial needs.

The LSAW steel pipe features a longitudinal welded line type, with outside diameters ranging from 355.6mm to 2320mm and wall thicknesses between 5mm and 50mm, making it suitable for various structural applications. Our 24 inch steel pipe is widely used in structure pipe construction and pipe piling projects.

We accept a minimum order quantity of 1 TON, with pricing between USD 650 and USD 1500 depending on specifications and customization. Packaging details are provided as per customer request, including transport packages such as black paint, bevel send, and end caps to ensure product protection during delivery.

Delivery time is guaranteed within 30 days from order confirmation. Payment terms include LC, TT, and other methods for your convenience. Choose JOHO for reliable and customizable LSAW steel pipe solutions tailored to your project requirements.

Support and Services:

Our LSAW Steel Pipe product is backed by comprehensive technical support and services to ensure optimal performance and customer satisfaction. We provide detailed product documentation, including specifications, installation guidelines, and maintenance instructions to help you utilize the pipes effectively.

Our experienced technical team is available to assist with product selection, engineering consultation, and troubleshooting to meet your project requirements. We also offer customized solutions tailored to specific industry needs, ensuring that our LSAW steel pipes perform reliably under various operating conditions.

Additionally, we conduct rigorous quality inspections and testing throughout the manufacturing process to guarantee product integrity and compliance with international standards. Post-delivery support includes guidance on storage, handling, and routine maintenance to extend the service life of the pipes.

For large-scale projects, we provide on-site technical assistance and training to facilitate proper installation and welding practices. Our commitment to continuous improvement ensures that our technical support evolves with emerging technologies and industry advancements.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!